The 3D model as a carrier of information for production

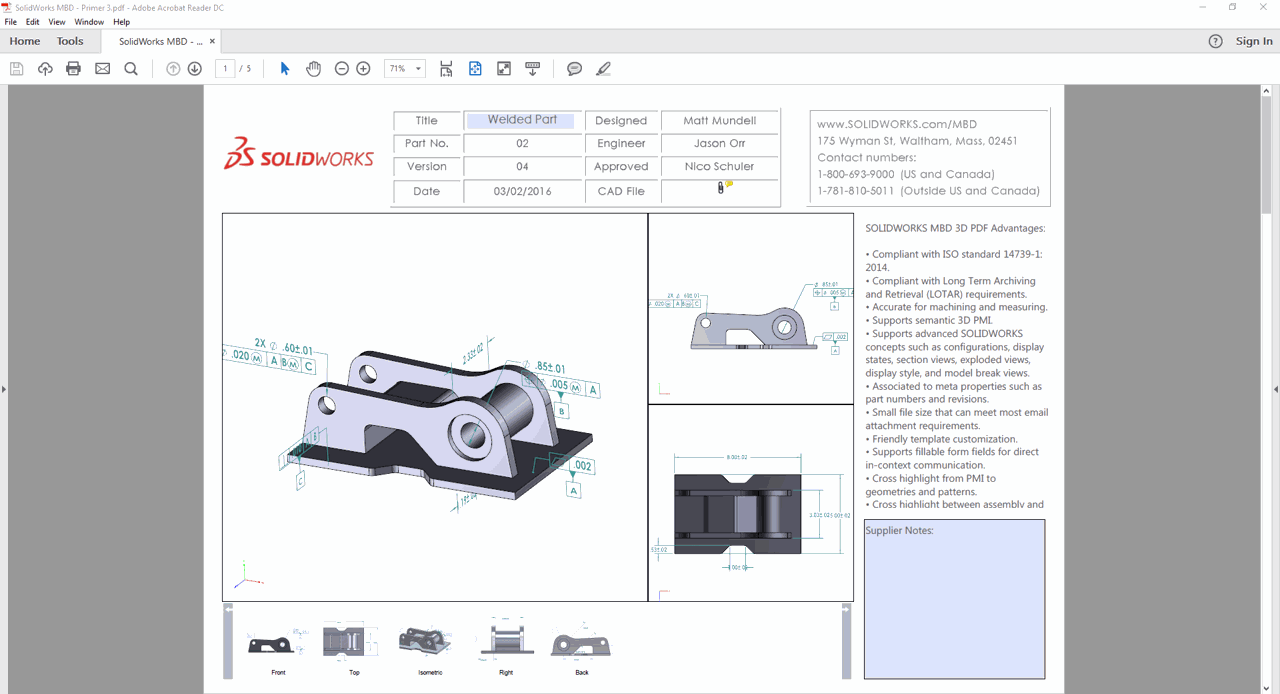

SOLIDWORKS MBD (Model Based Definition) is a new approach in defining all the information necessary for production (dimensions, tolerances, additional specifications) and control of the 3D model itself. This approach to production and control brings significant time and monetary benefits compared to the traditional approach of combined use of 3D models and technical drawings.

Companies that opt for the SOLIDWORKS MBD solution notice, after a few months of use, a significantly smaller number of manufacturing errorsa and reduced waste and time spent on product repairs ...

SOLIDWORKS MBD enables users to define, organize and publish 3D PMI (Product Manufacturing Information) data in standard file formats such as 3D PDF and eDrawings. SOLIDWORKS MBD supports many industry standards (ISO, DIN, ASME ...).

Production without papers or drawings?

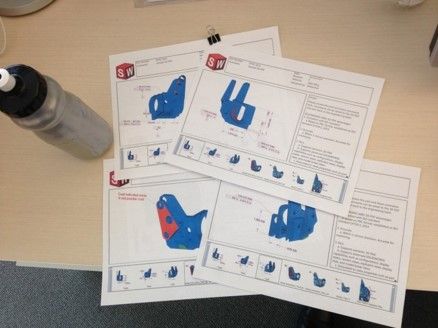

Production without drawings does not mean production without papers. The only place of truth is the 3D model, and the drawings are automatically generated reports that do not make any changes to the 3D model!

AIf you need a drawing, generate it like a PDF report. If you do not need it, the 3D model contains all the information you need to produce a part or assembly!

Basic functions

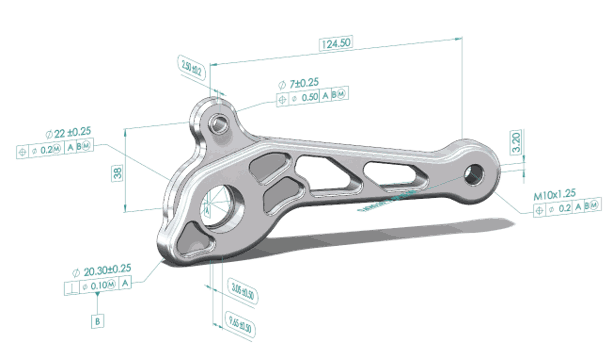

Defining the parameters for production

Using advanced tools, SOLIDWORKS MBD can manually, semi-automatically, and automatically quote 3D models, as well as tolerate them, taking into account tolerances of shape and position. In a 3D environment, a component can be created that is tailored to the client's needs as well as defining various notes.

3D PDF as an information carrier

The ubiquity and openness of 3D PDF makes it the ideal format for transferring product data, thanks to the following functionalities:

-

Automatic creation of 3D PDF-a (with a click)

-

Model display in many views and cross sections

-

Free rotation, cross-section and measurement of 3D models

-

Dynamic component

-

Comment entry

-

Defining prohibitions (prohibition of cross-section creation, measurement ...) in order to preserve intellectual property

Creating 3D PDF templates

SOLIDWORKS MBD includes a tool for creating 3D PDF templates that allows you to customize 3D PDF and output MBD content to client needs.

Integration with SOLIDWORKS CAM

The quotes and tolerances created using the SOLIDWORKS MBD software are automatically recognized by SOLIDWORKS CAM when creating a CAM program. This eliminates the double insertion of tolerances, both in the technical drawing and in the CAM program.

Integration with SOLIDWORKS 3D CAD

SOLIDWORKS MBD is fully integrated into SOLIDWORKS 3D CAD software and can take advantage of its many functionalities (Annotation and Break views, Configurations, 3D Model Parameters ...).

Quick creation of 2D technical drawings

When there is an explicit requirement to create 2D documentation, the SOLIDWORKS 3D model with the MBD data required for production can also be used to quickly create traditional 2D technical drawings. All data defined in the 3D environment is automatically transferred to the 2D technical drawing.

Do you need SOLIDWORKS MBD?

Do you have development, technology and production?

Traditionally, technology communicates development through workshop drawings and makes operational drawings that go into production, but the 3D model, as a carrier of information about tolerances and dimensions, provides technology with a much larger amount of data than is needed. The 3D model, as the only link between development and technology, eliminates workshop and assembly drawings.

Do you do serial production and feel that the moment has not yet come to get rid of the drawings??

Unless you start defining all the information you need to produce on a 3D model now, one day you will have to go back and do a double job. Define all tolerances and dimensions on the 3D model now, continue to use the drawings in the transition period, and switch to the 3D model completely in a year or two.

Do you have a complex product?

The component from the 3D CAD software displays information from the 3D model, and the drawing contains other additional information that may affect the modified specification for procurement and production. Often, drawings and models are out of tune and changes are inevitably made, breaking deadlines and generating costs. By integrating production data into 3D CAD software, these problems are eliminated.

F.A.Q. (Click on the question for the answer)

We work in batch production, we have development, technology, and production. Technology communicates with development through workshop drawings and makes operational drawings that go into production. Do we need structural workshop drawings?

Answer:

You do not need the drawings because they do not end up in production. Production for each technological operation receives an operation sheet and for each control operation a control plan or control scheme. Technologists themselves would rather get a 3D model with tolerances than work side by side with a 3D model and read a 2D drawing with tolerances.

We are engaged in individual production. We have our own tool development and construction, we manufacture parts ourselves on CNC machines and use CAM software. Do we need a drawing?

Answer:

You don't need a drawing. From the 3D model, you go into the CAM software where technological operations are defined and you have the tolerances at all times. You handle everything faster and there is less of a chance of missing something and making a reject. The machine operator receives a G-code, based on which the CNC machine creates the part. Everyone in the company has a 3D model available via mobile, tablet or desktop and can be viewed in 3D PDF.

Quality control uses workshop drawings and draws up control plans based on them. How will it work without a drawing?

Answer:

You don't need a drawing anymore because SolidWorks Inspection uses a 3D model with dimensions and tolerances to create control plans. SolidWorks Inspection is part of the overall ecosystem for the application of MBD and 3D PMI principles in production.

Does quality control use coordinate measuring machines or 3D scanners to check critical dimensions and tolerances?

Answer:

Modern inspection software has the ability to import 3D models with tolerances, which reduces the process of preparation for control from a few hours to a few minutes.

Even if I adopt the MBD and 3D PMI principle of work in my company, how do I get clients and suppliers involved in the whole system? They will never adjust. They use other software solutions and we will not be compatible!

Answer:

To nije tačno, obzirom da SolidWorks MBD generiše izlaznu dokumentaciju u 3D PDF formatu koja je mnogo bolja i informativnija za kupce i naručioce posla od tehničkih crteža. Korisnici SolidWorks PDM softvera nemaju potrebu za bilo kakvim softverom jer on u sebi sadrži prikaz modela sa tolerancijama. eDrawings korisnici imaju mnogo više opcija nego što je prisutno u 3D PDF formatu. SolidWorks MBD može da eksportuje model u STEP 232 format koji predstavlja novi standard za razmenu dokumentacije između 3D CAD sistema i on pored 3D geometrije sa sobom nosi i informacije o dimenzijama i tolerancijama!

Pogledajte donje primere i otvorite ih direktno iz Adobe Acrobat Readera kako biste imali sve opcije:

In some places in manufacturing and assembly, I need to have a paper with drawings and instructions and I have a few pre-retirement workers who do not want to change. How can I overcome these problems?

Answer:

Production without drawingz is not production without paper. A 3D PDF that is automatically generated from a 3D model can be printed and used as needed. You don't have a drawing, but you can distribute the paper where you need it.

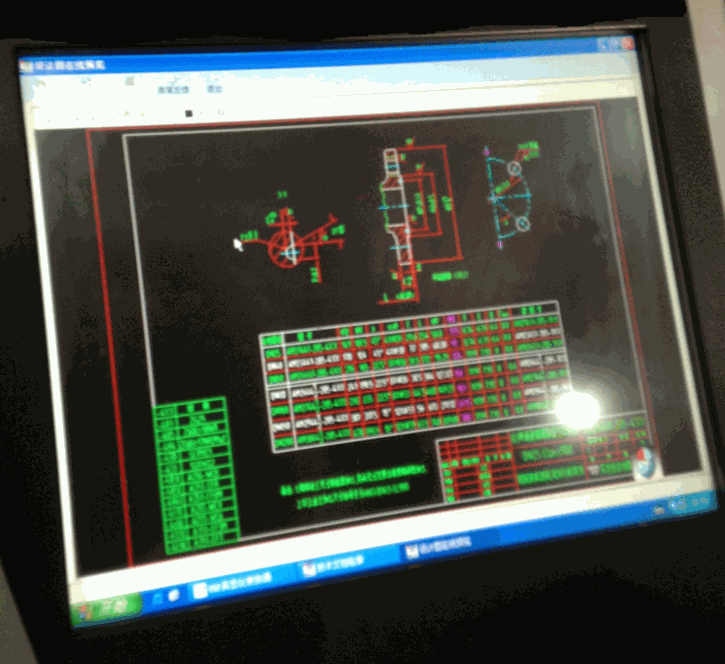

We already have all of this because we have computers installed all over the company where we look at the documentation!

Answer:

It is a mistake to think that a screen in manufacturing means production without drawing. That is paperless manufacturing. If you display a drawing on the screen, you still have two places of truth, one is a model and the other is a drawing. You may want to update the drawing, but not the model and create a reject on the CNC machine because the 3D model is used to create the control code, not the drawing!

SOLIDWORKS MBD primeri

Proizvodnja bez crteža ne znači i proizvodnja bez papira. Jedino mesto istine je 3D model, a crteži su automatski generisani izveštaji u koje se ne unose nikakve izmene u odnosu na 3D model!

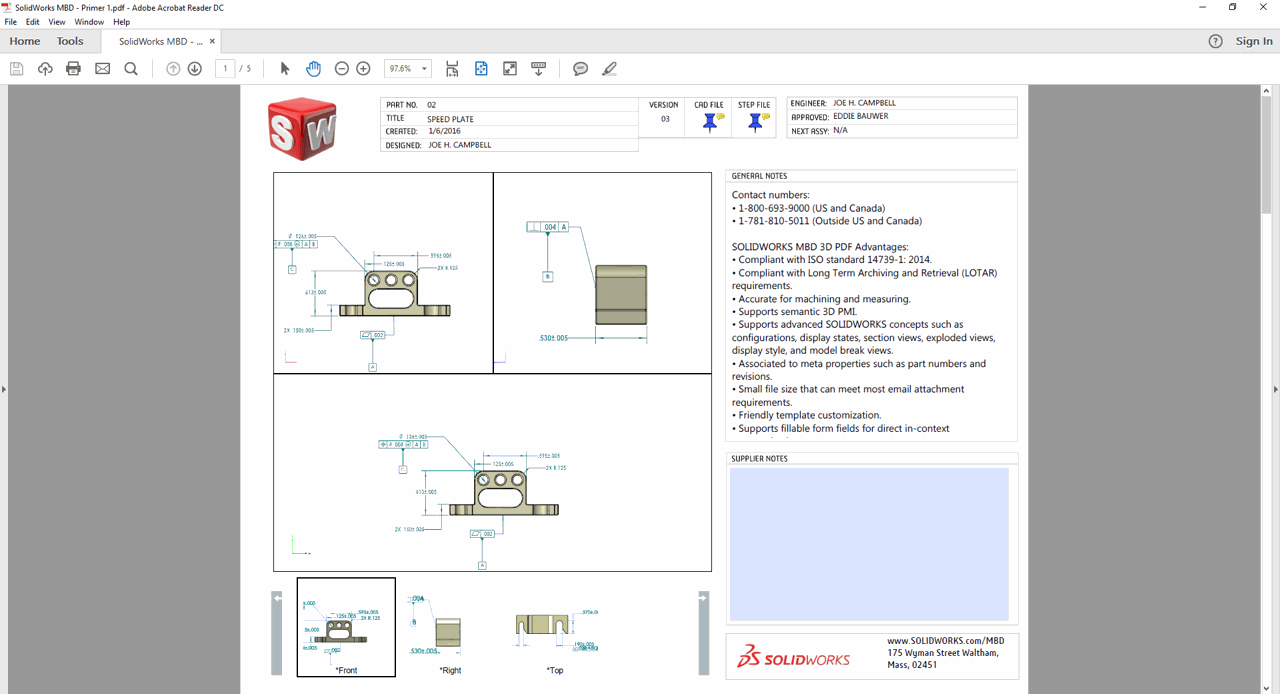

3D PDF Primer 1

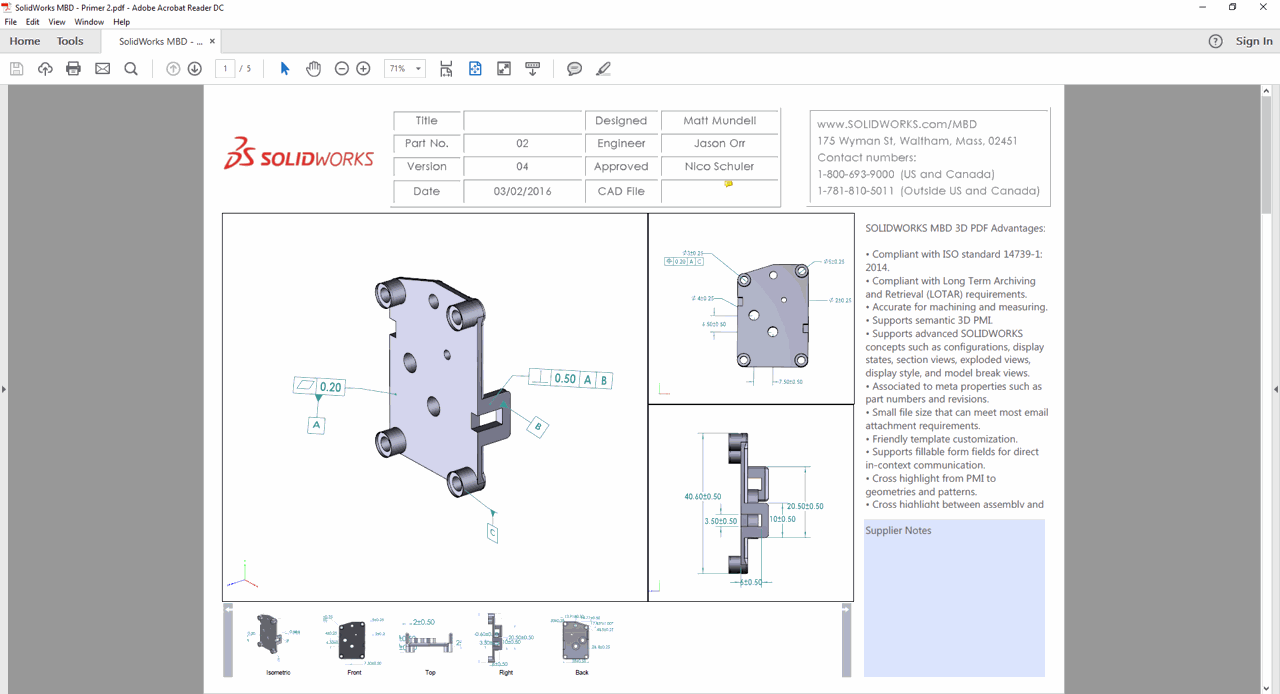

3D PDF Primer 2

3D PDF Primer 3